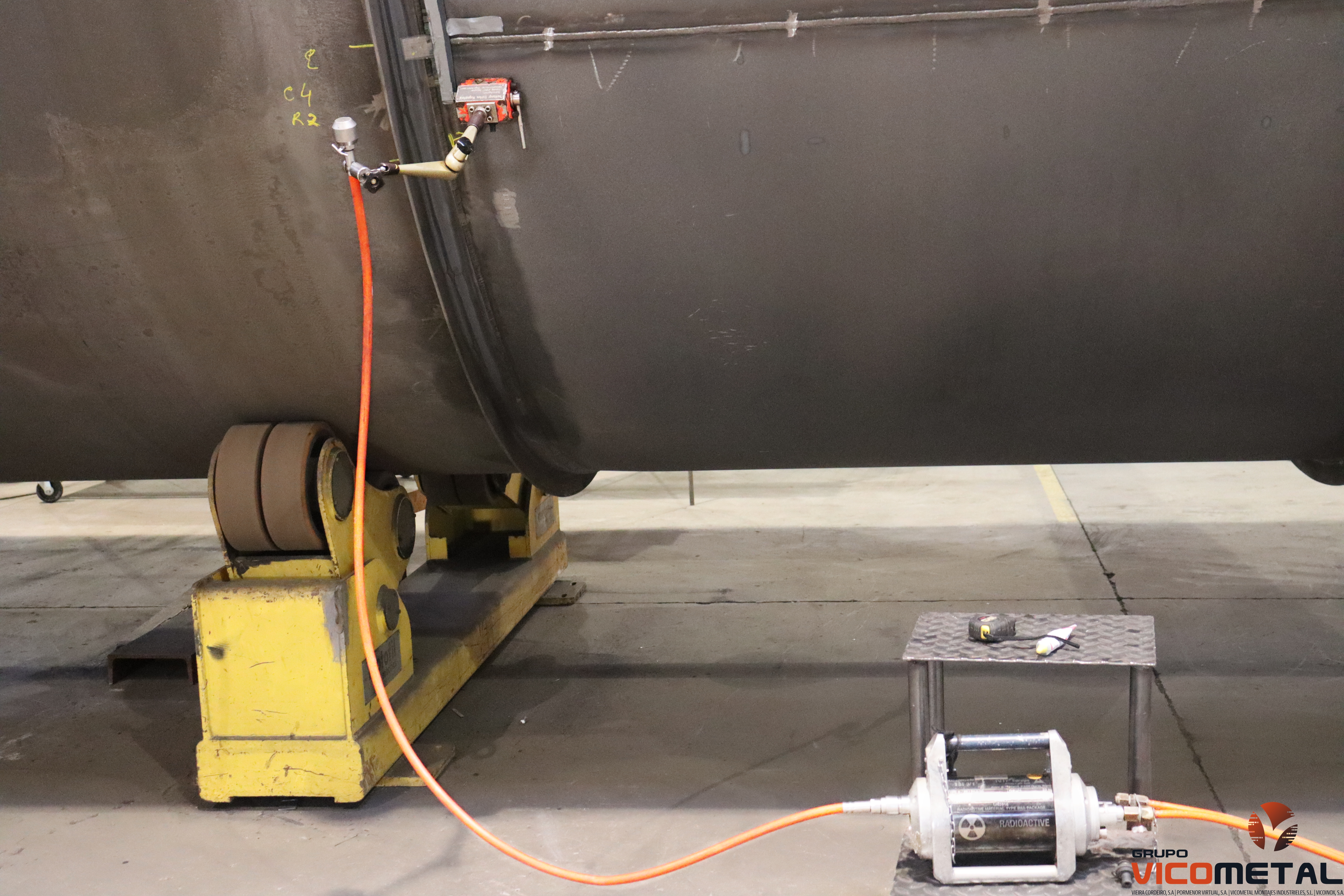

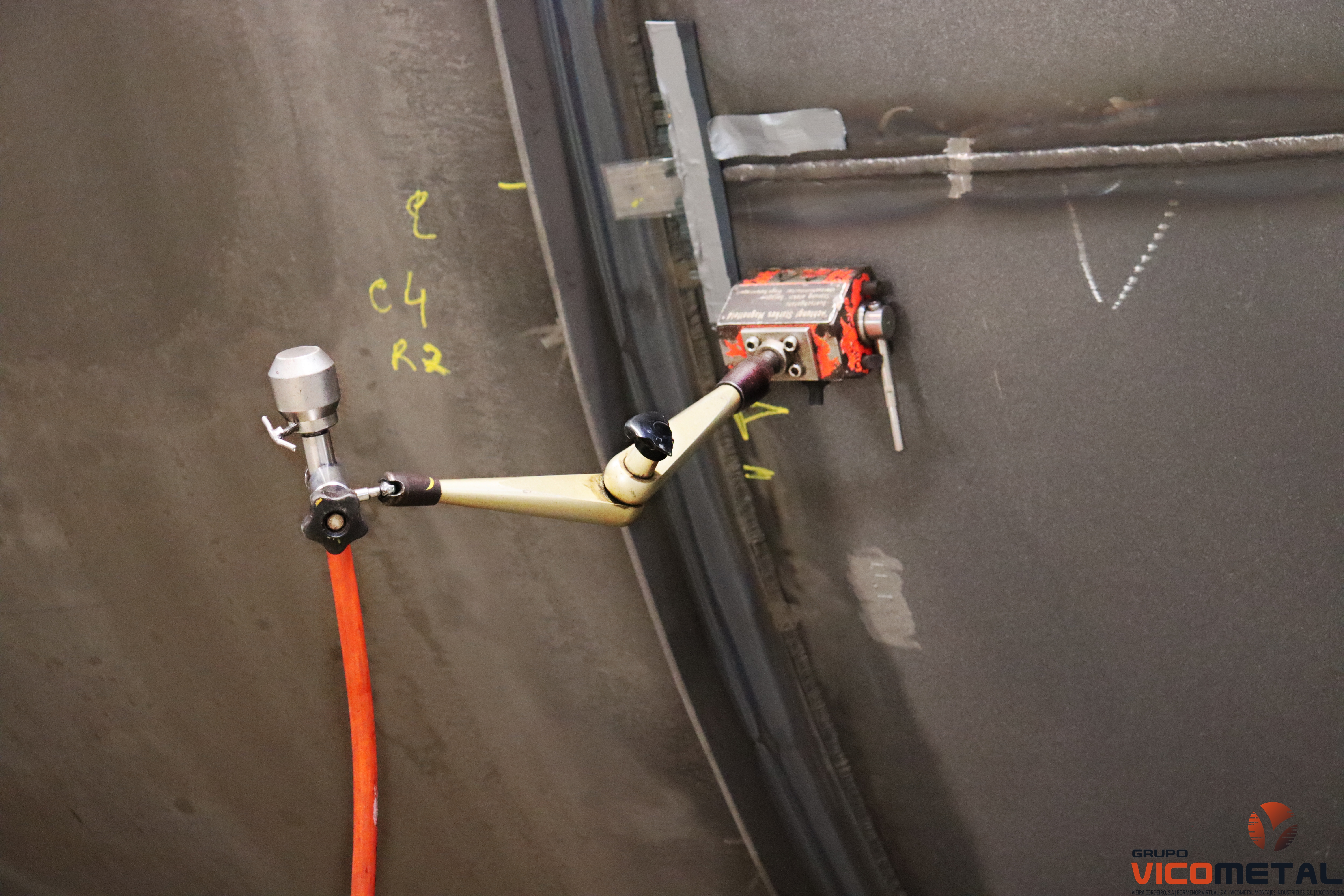

Moments before the radiographic test with gamma rays (gamagrafia) to be carried out on the end-to-end joints of the Silo.

Tests were also carried out on:

* Magnetic particles and penetrating liquids for detecting surface imperfections;

* Ultrasound for detection of internal imperfections in thicknesses greater than or equal to 10mm.

These tests are carried out to test and guarantee the soundness and compactness of the welded joints., ensuring compliance with quality requirements in the production of defect-free gaskets.