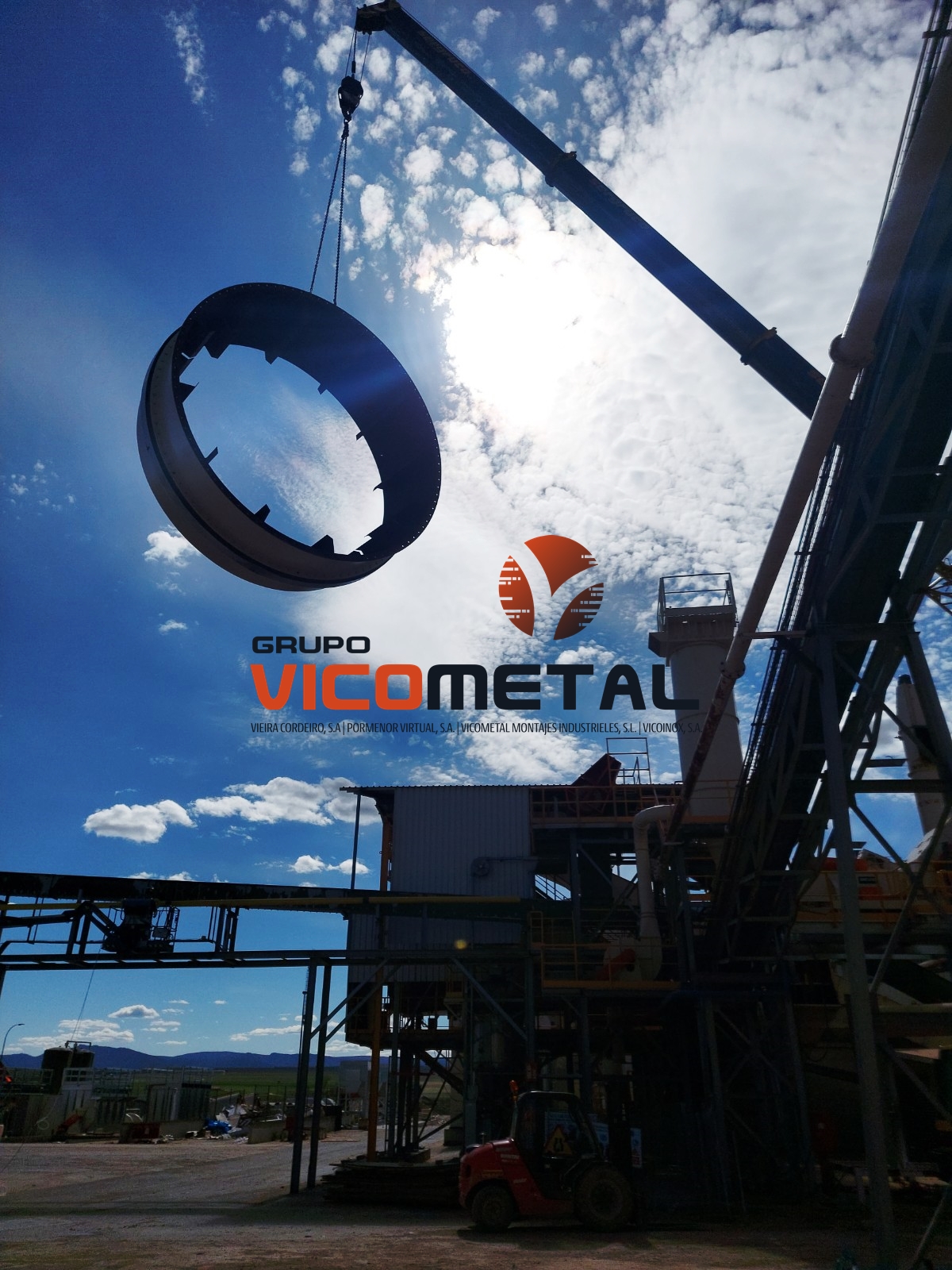

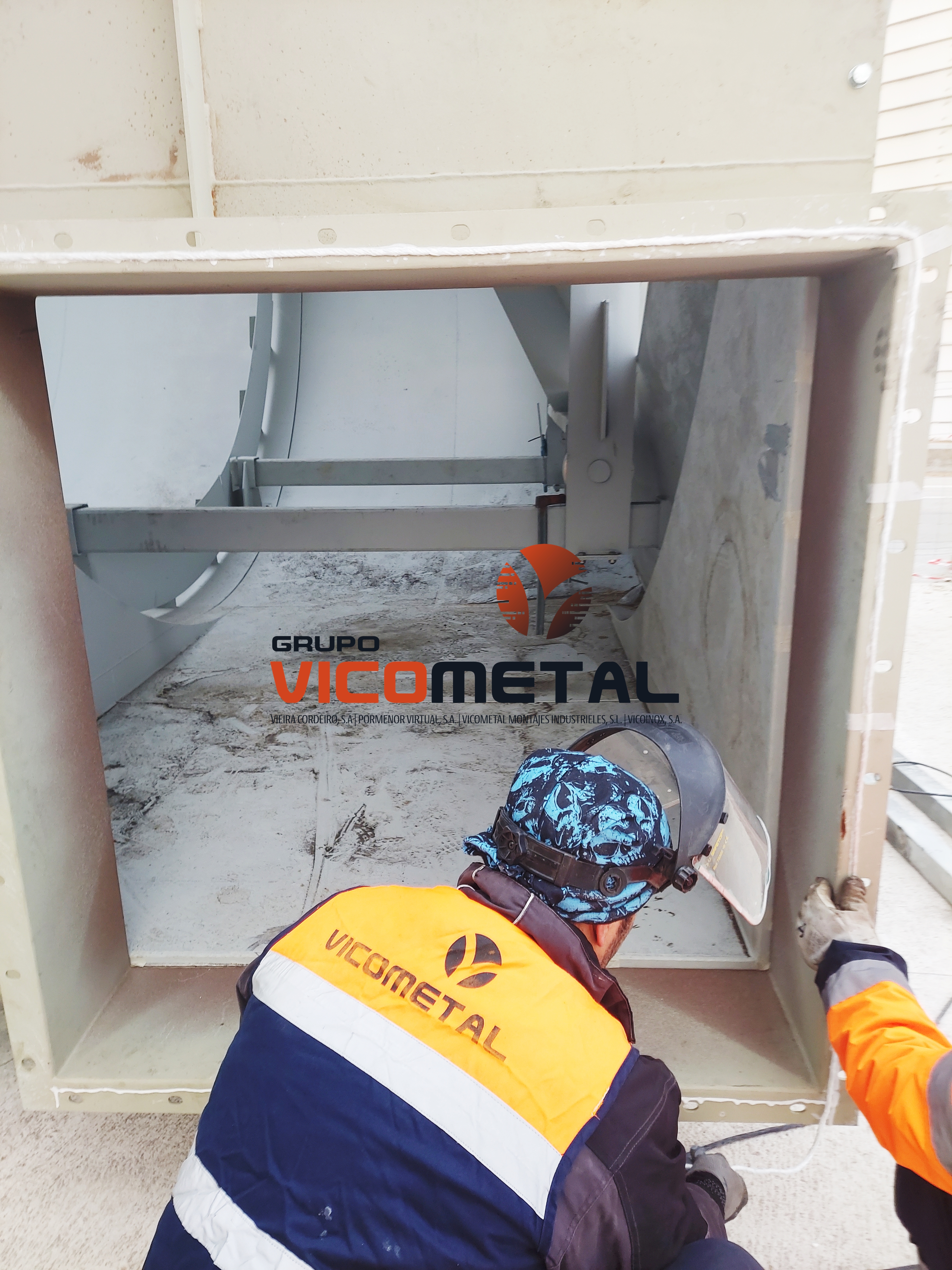

in this final stage, we present the headbox that was manufactured by Vicometal, where the material (madeira) wet enters the drum with the aim of leaving completely dry through the outlet box, for forwarding the product to the remaining stages of production.

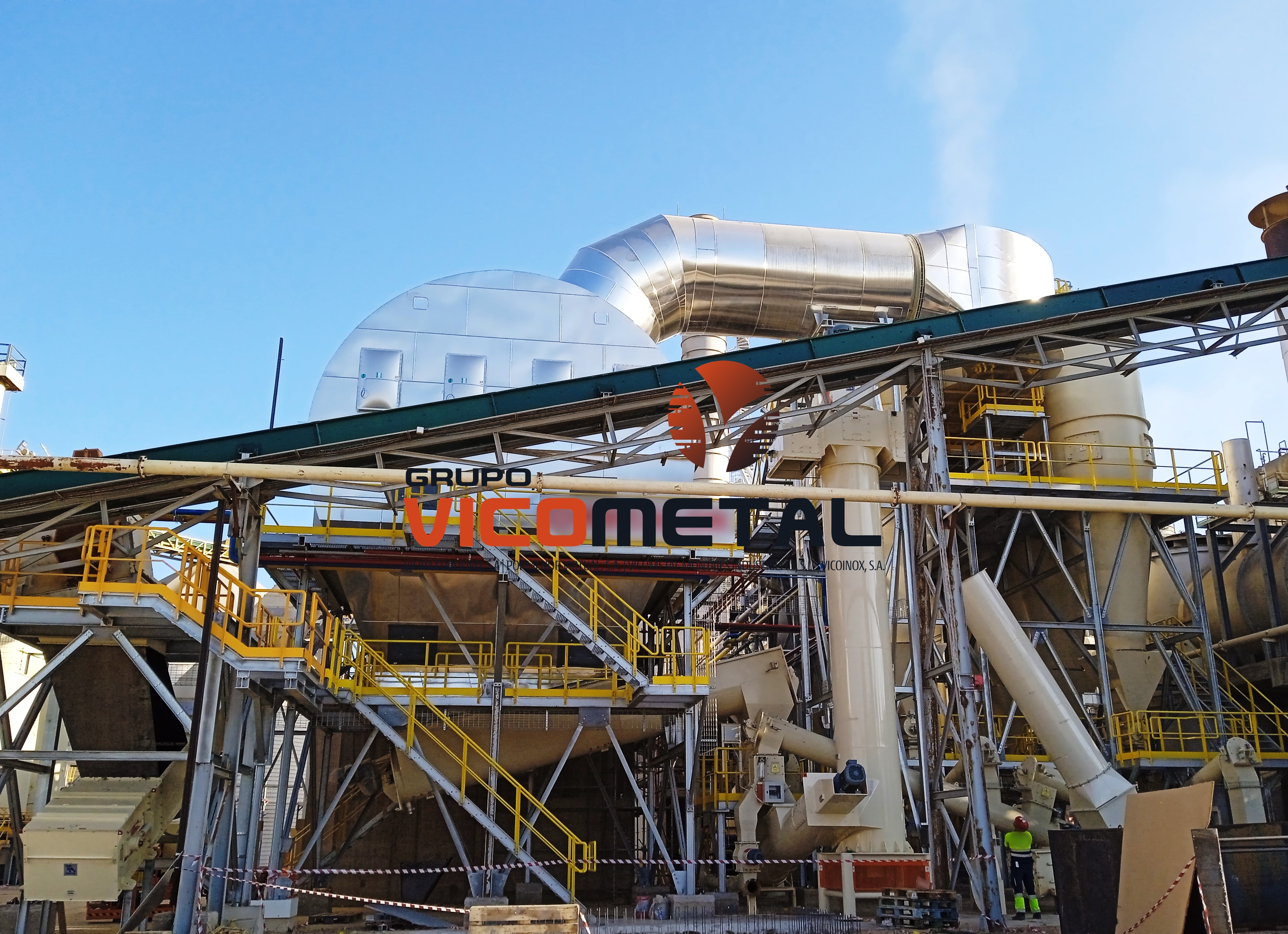

Once the work is finished, you can also see the photographic record of the complete work.