2st phase of work

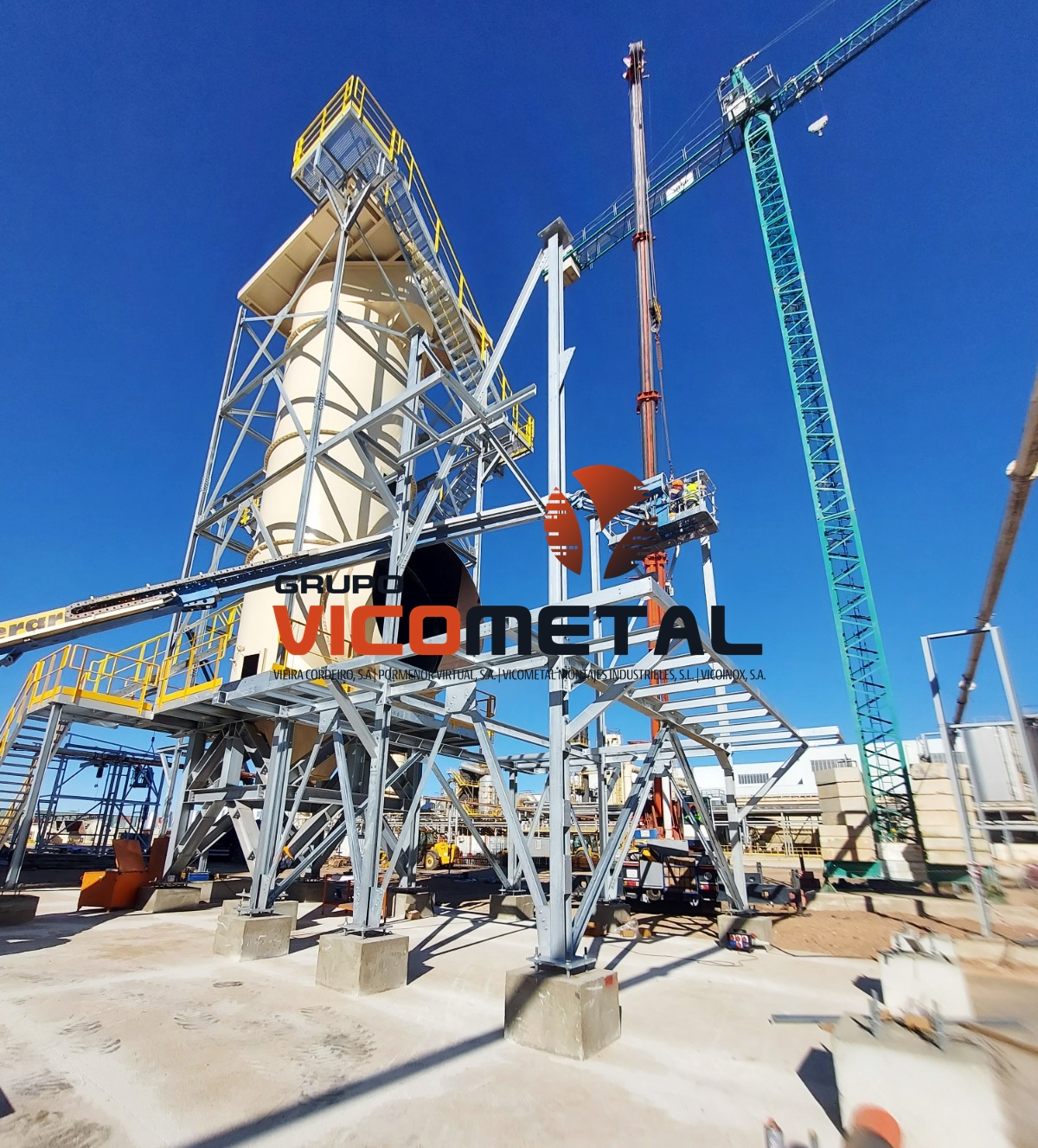

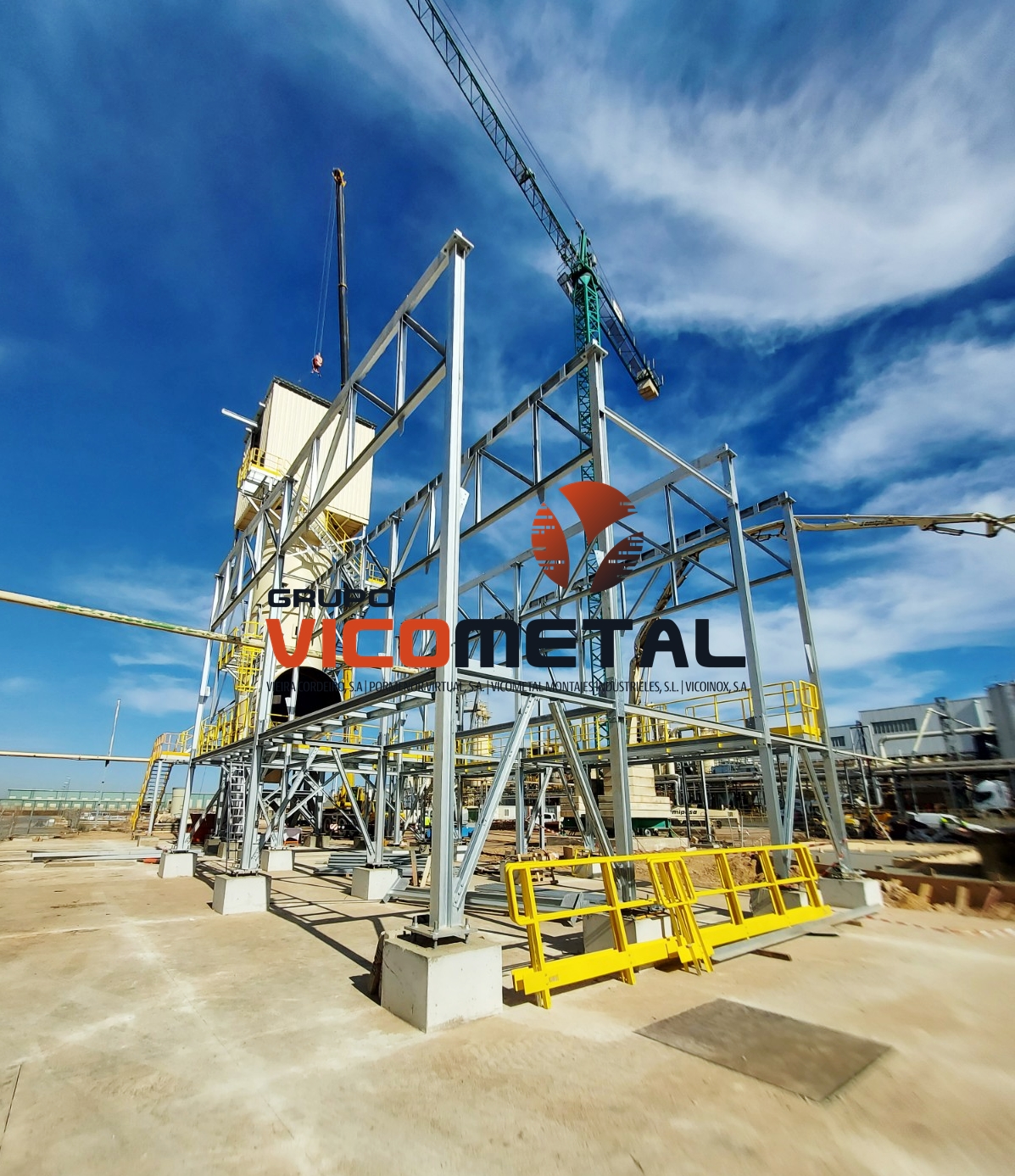

The continuation of the work concerns the assembly of Cyclones for suspending sand from Biomass and the respective extractor assembly.

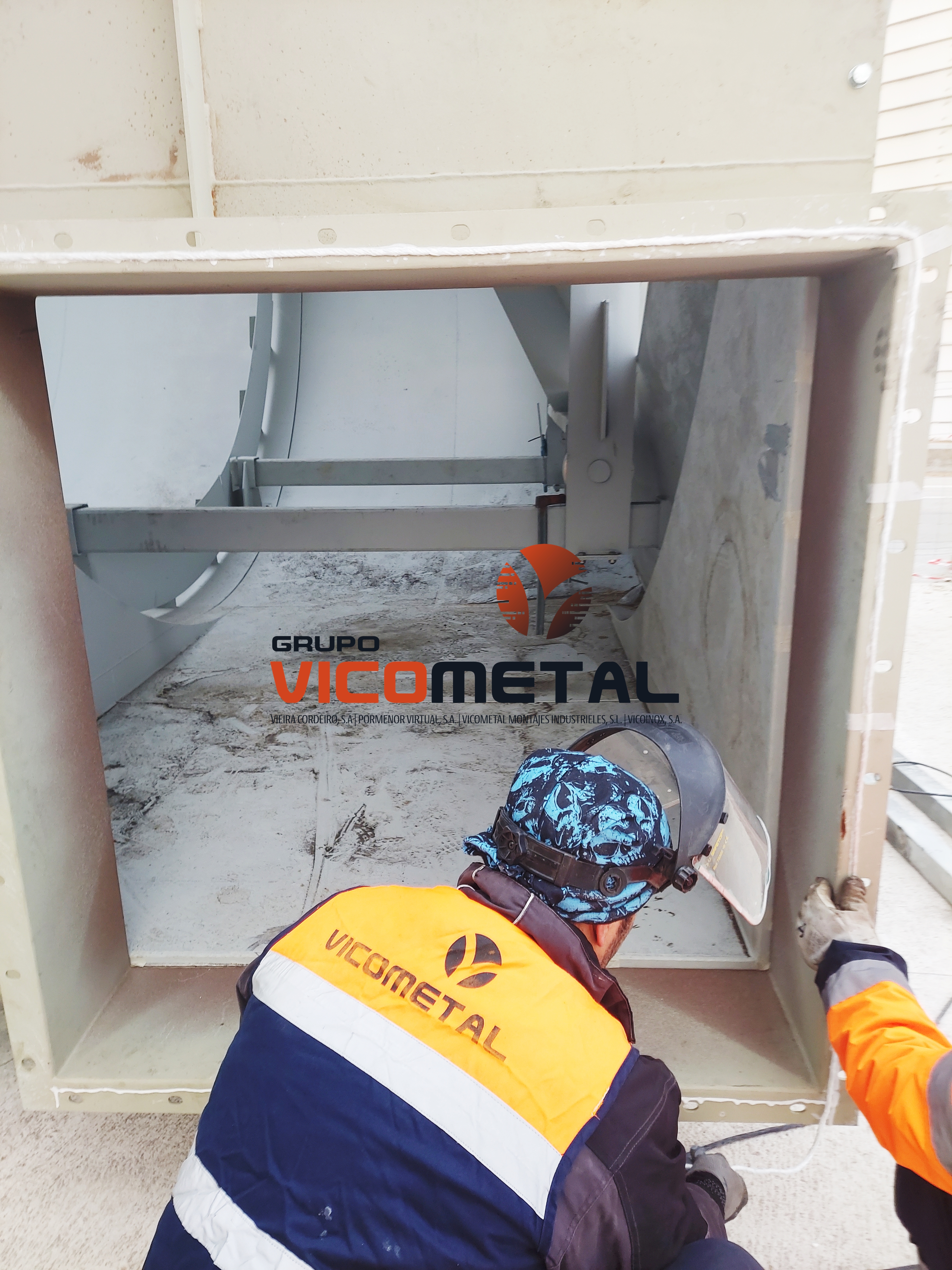

Then, the pre-assembly of the mixing chamber was carried out., composed of two main parts and its exterior, this chamber aims to ensure temperature control of the gases that go to dry wood in the drum by mixing with colder gases from an existing installation.

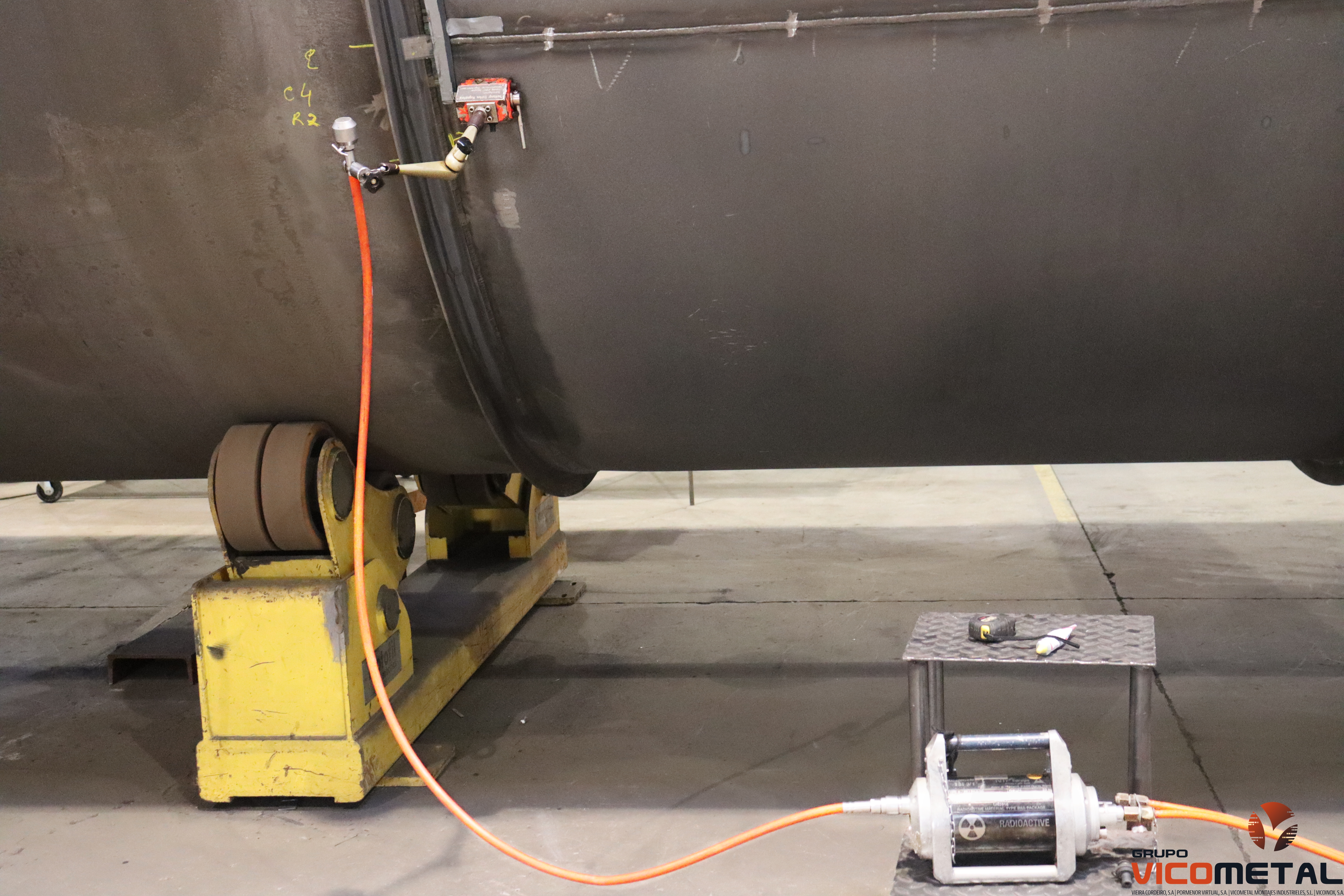

The cyclones were produced at Vicometal.

3st phase of work

At this stage of the work, Cyclones were assembled to separate the dust from drying the wood in the drum and two fans were installed for routing gases to an electrostatic filter..

Cyclones were produced by Vicometal.